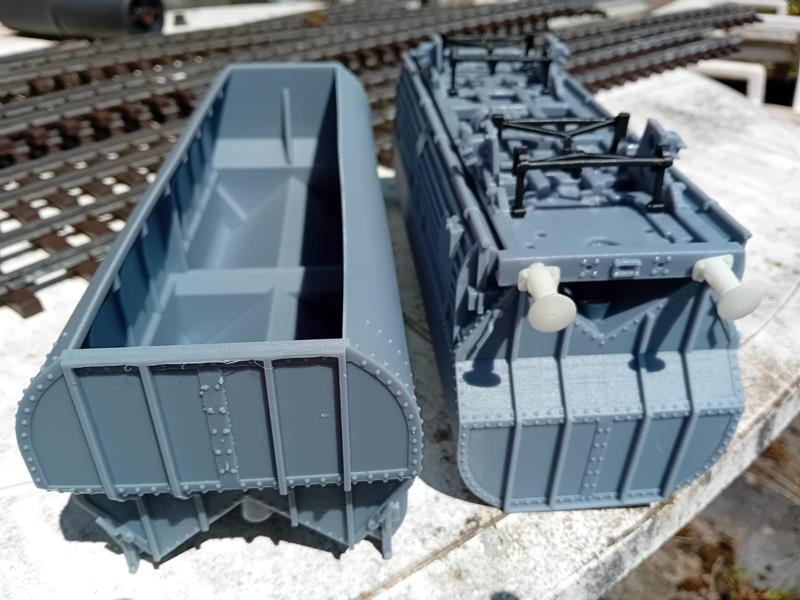

French Arbel hopper wagon

A resin print representing the coal/coke hopper manufactured by Arbel. This is a simple model with basic underframe detailing. The frame is designed to take 6mm od bearings. Due to the multiple choices of couplings and wheel standards neither couplers nor wheelsets are supplied but buffers (rarely shown attached here) are. I understand that decals are being produced and sold elsewhere.

I hasten to add that I did not do the design work. I have not been able to check the dimensions and features with the full size item and hence I refer to it as 1:32 semi-scale.

Please understand that this is a hobby printed item. There will likely be imperfections which a small amount of body filler and careful use of a blade and/or abrasive paper would rectify. The resin chosen has a reasonable tolerance to hot weather and a test beam span (with a mid point load) of the preceding resin version from the same firm has been subject to a 15 month outdoor test in central france. Creep has been observed but it is minimal. If the items are brought out for occasional use they seem to withstand southern france temperatures.

If you need the definition of an injection moulded part or the decades long lifespan of a fine brass or diecast model then please look elsewhere. I mention that the phone lens appears to have introduced some distortion.

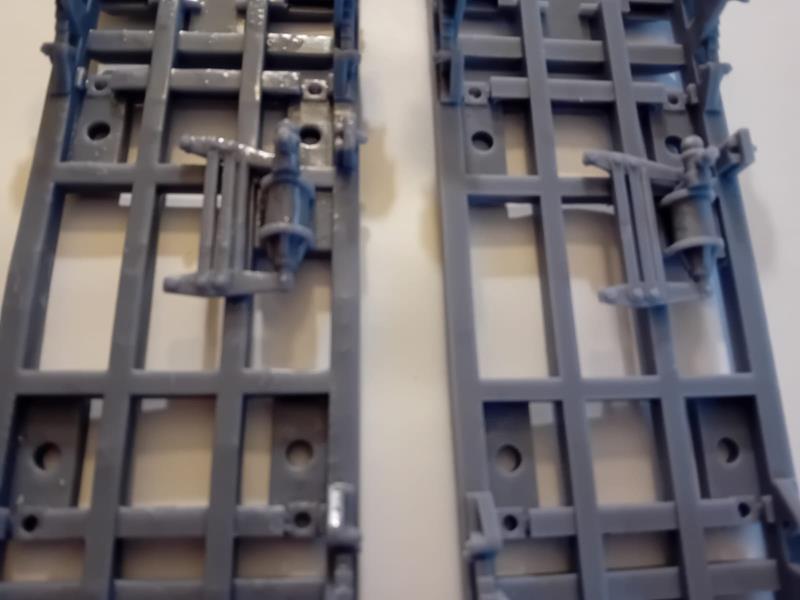

What is on offer is the main hopper body and the underframe with the some detailing such as the buffers, brake cylinder, hangers and shoes.

The hopper body can be used with or without the hold-together tubes. Personally I do not think these are needed but to simplify my stock I am printing with and you may cut them off.

Sprung buffers can be supplied as an additional cost upgrade.

The frame is designed to take 6mm od bearings. 6mm od , 3mm bore ballraces can be supplied as an additional cost upgrade

Wheelsets are not currently offered since there are a number of standards within gauge 1. Similarly couplers are not provided due to the range of styles used. Should there be demand a solid north american style knuckle type could be provided or alternatively one that could work with the Maerklin coupler.

The initial resin frame had no form of suspension. There will be a minimal amount of flex in the plastic but you should assume that the flange depth is all that there is to help on uneven track. A trial sprung frame has since been developed, at the moment the springs obtained are too stiff for my liking, it may as well be unsprung, but weaker springs have been ordered.

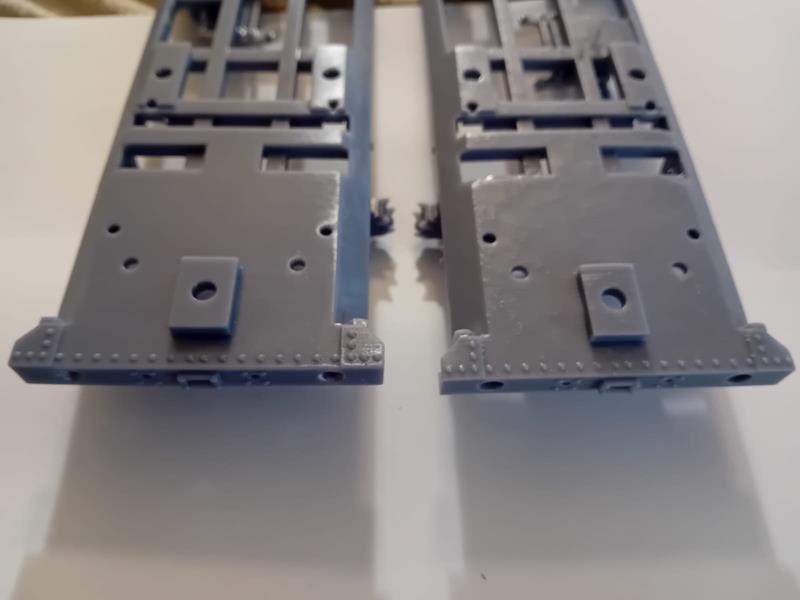

There is a further decision to be made regarding the frame: It can be printed to give better detailing to the upper surface or to the lower. I had assumed with the wagon sat on a track or other surface that upper detailing would be more important however potential customers tell me that a crisper appearance on the underside is more important and I tend to agree.

The basic hopper body and frame, brake hangers and solid buffers is priced at 80 euros.

add 6 euros for a set of ball bearings

add 6 euros to substitute sprung buffers.

Please state whether you want to favor the upper or lower frame detailing and whether you want the mounting tubes or not.

If these are not specified then the default is to aim for the better underframe and leave the mounting tubes (which you could remove).

Shipping would be from france and is an extra cost. Import duties to other countries are not covered. For batches it may be more efficient for you to suffer the clearance charges that the delivery system might impose. For one or two hoppers it might make more sense for me to list using the ebay global shipping program but the price would increase to cover their fees and I wish you luck if you ever have to contact pitney-bowes regarding a problem.

Regarding assembly you may want to paint the components first. My suggestion is that you then fit the brake hangers to the frame. Next you may need to trim the axles of whatever wheelsets you intend to use. The axles should be 63 mm wide, the distance between bearings is 58mm so please space appropriately between the wheels and bearings.

For the unsprung version I think it will be easier if the bearings are fitted to the axle and then the bearings inserted in to the frame. The frame should spring back but as a precaution you may want to use a weight or make a jig to press the axle boxes together after the axles have been inserted and hold in that position for an hour to help the resin return to position. If the sprung chassis is offered I would suggest that the springs and bearings are placed in the axle boxes first and the wheelset then inserted in to the bearings.

With the wheels in place you then have the running chassis to let you attend to the couplings.

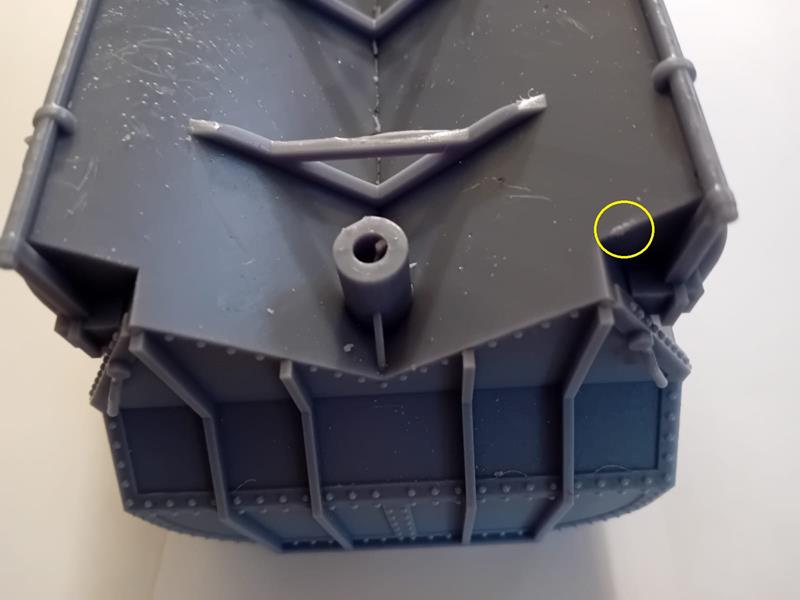

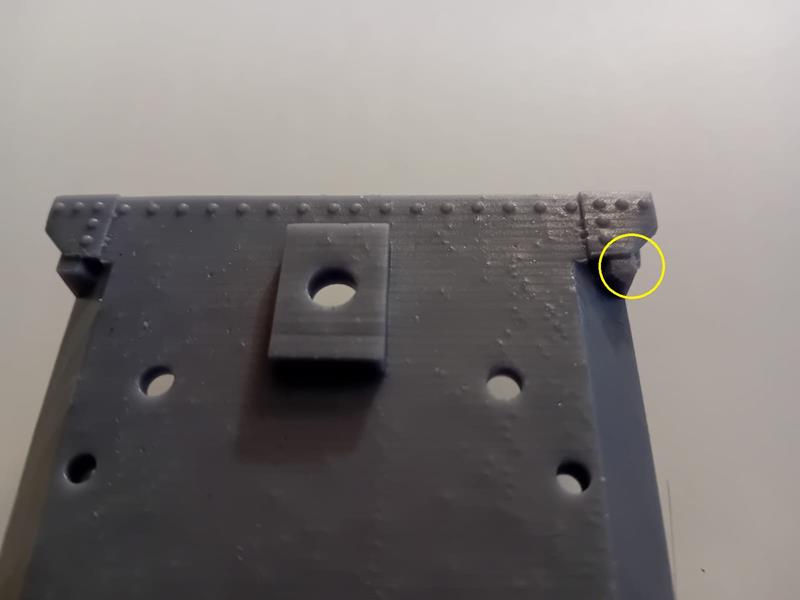

The hopper body should be a tight press fit on the frame. You may find that a small easement at one or two of the points shown may assist. If you opted for the attachment tubes use those otherwise some araldite or similar will glue the body to the frame.

Finally the buffers can be glued to the frame.

For decals I suggest you contact Mr. Duhamel (who had the idea to produce the hopper to 1:32) directly or via g1mra france.

Regarding wheelsets I have now received an initial batch of 26mm diameter rims intended for american freight and am sufficiently happy to have ordered a 28.5mm batch (equating to 912mm, 36") which is not too far off the euro freight standard for this era. Commercial wheelsets are available from Maerklin, Bachman and others if you do not want to make your own.

other 1:32 items